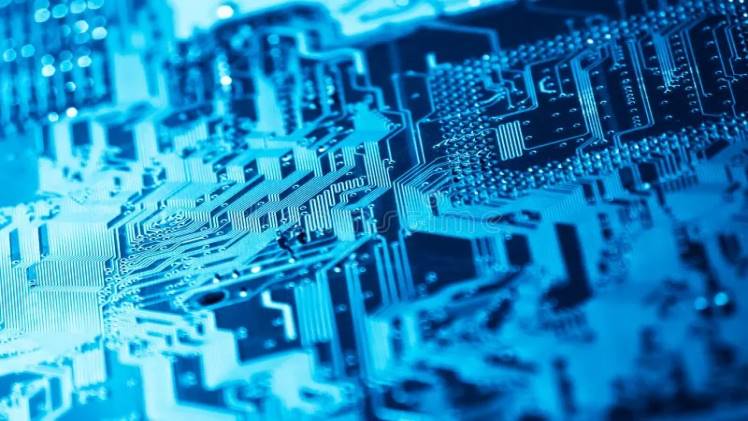

Blue PCB: Unveiling the Mysteries of This Remarkable Circuit Board

When it comes to electronic devices and gadgets, the inner workings can often seem mysterious and complex. Behind the sleek exteriors lies a world of intricate circuitry, and one crucial component that plays a significant role is the Printed Circuit Board (PCB). Among the various types of PCBs available, one that has been gaining attention in recent times is the Blue PCB. In this article, we will explore the intriguing world of Blue PCBs, their characteristics, applications, and what makes them unique.

Understanding Blue PCBs

A PCB serves as the foundation for connecting and supporting electronic components in a device. The Blue PCB, as the name suggests, refers to a type of PCB that comes in a distinctive blue color. The color is not merely an aesthetic choice; it has functional significance as well. Blue PCBs are typically made using a fiberglass material known as FR-4, which is impregnated with epoxy resin and reinforced with a layer of copper traces.

Benefits and Advantages of Blue PCBs

Blue PCBs offer several advantages over their counterparts. Let’s delve into some of the key benefits associated with these remarkable circuit boards:

- Visual Contrast: The vibrant blue color of these PCBs provides excellent visual contrast, making it easier for technicians and engineers to identify and troubleshoot any issues that may arise during the manufacturing or assembly process. The contrasting color helps enhance the overall visibility of the circuitry, improving efficiency and reducing the chances of errors.

- High Thermal Resistance: Blue PCBs are known for their excellent thermal resistance properties. The epoxy resin used in their construction helps dissipate heat effectively, ensuring that the components operate within their specified temperature ranges. This thermal stability contributes to the longevity and reliability of the devices utilizing Blue PCBs.

- Moisture Resistance: Moisture and humidity can pose significant risks to electronic components. Fortunately, Blue PCBs are equipped with a protective layer that shields the circuitry from moisture, preventing corrosion and electrical malfunctions. This moisture resistance feature makes Blue PCBs highly suitable for applications in environments with high humidity levels or exposure to moisture.

- Enhanced Durability: The combination of the fiberglass material and the epoxy resin imparts robustness and durability to Blue PCBs. These circuit boards can withstand mechanical stress, temperature variations, and vibrations, making them ideal for applications in rugged environments.

Applications of Blue PCBs

Blue PCBs find application in a wide range of industries and electronic devices. Let’s explore some common areas where these circuit boards are extensively used:

- Consumer Electronics: Blue PCBs are widely utilized in various consumer electronics such as smartphones, laptops, televisions, gaming consoles, and audio devices. Their reliability, thermal resistance, and durability make them a preferred choice for manufacturers aiming to deliver high-quality products to consumers.

- Automotive Industry: The automotive industry demands robust and reliable electronic components that can withstand the harsh conditions of automotive environments. Blue PCBs, with their exceptional durability and resistance to temperature fluctuations and vibrations, are employed in automotive control systems, infotainment systems, and engine management units.

- Aerospace and Defense: The aerospace and defense sectors require electronic systems that can function flawlessly even under extreme conditions. Blue PCBs, known for their thermal resistance and reliability, are employed in avionics, satellites, navigation systems, radar systems, and communication devices used in aerospace and defense applications.

- Industrial Automation: Blue PCBs play a vital role in industrial automation, where precise and efficient control systems are required. These circuit boards are used in programmable logic controllers (PLCs), motor control systems, robotics, and monitoring equipment. The durability and moisture resistance of Blue PCBs make them suitable for industrial environments.

- Medical Devices: In the medical field, precision and reliability are paramount. Blue PCBs are utilized in various medical devices such as patient monitoring systems, diagnostic equipment, imaging devices, and implantable devices. The thermal stability and moisture resistance of Blue PCBs ensure the accurate and continuous operation of these critical medical devices.

What Makes Blue PCBs Unique?

Apart from their distinct blue color, Blue PCBs offer unique characteristics that set them apart from other types of circuit boards:

- Aesthetics: The blue color of these PCBs adds an aesthetic appeal to electronic devices. It can be particularly appealing for products targeting a specific market segment or those aiming to differentiate themselves from competitors.

- Branding and Recognition: Some companies choose Blue PCBs as part of their brand identity. The visual association of blue circuit boards with a particular brand or product can help create a recognizable and memorable image among consumers.

- Visual Differentiation: Blue PCBs provide clear visual differentiation in the manufacturing and assembly processes. This makes it easier for technicians to distinguish between different circuit boards and ensures correct placement of components, reducing errors and improving efficiency.

- Marketing Potential: The uniqueness of Blue PCBs can be leveraged as a marketing tool. Manufacturers can highlight the utilization of Blue PCBs in their products to showcase superior quality, durability, and advanced technology to potential customers.